Non-ferrous metals are the hidden champions that shape our modern world. These metals, distinguished by their absence of iron, boast properties that make them essential across countless industries. They are more than just materials; they are the innovators and sustainers of technology. From the aluminum that forms your drink cans to the copper conducting electricity in your walls, these metals are omnipresent, silently powering our everyday lives.

Non-ferrous metals are chosen for their specific traits that outperform other options for particular jobs. They are the pillars of progress, forming the foundation upon which new technologies are built. Their impact is profound, fueling advancements in sectors as diverse as transportation, construction, and even the exploration of outer space.

In this exploration, we'll uncover the diverse roles of non-ferrous metals, their benefits, and how they're employed across various industries to meet the challenges of today and tomorrow. Prepare to be captivated by the story of these extraordinary elements and learn how they continue to revolutionize our industries and contribute to a sustainable future.

1. Exploring the Vibrant World of Non-Ferrous Metals

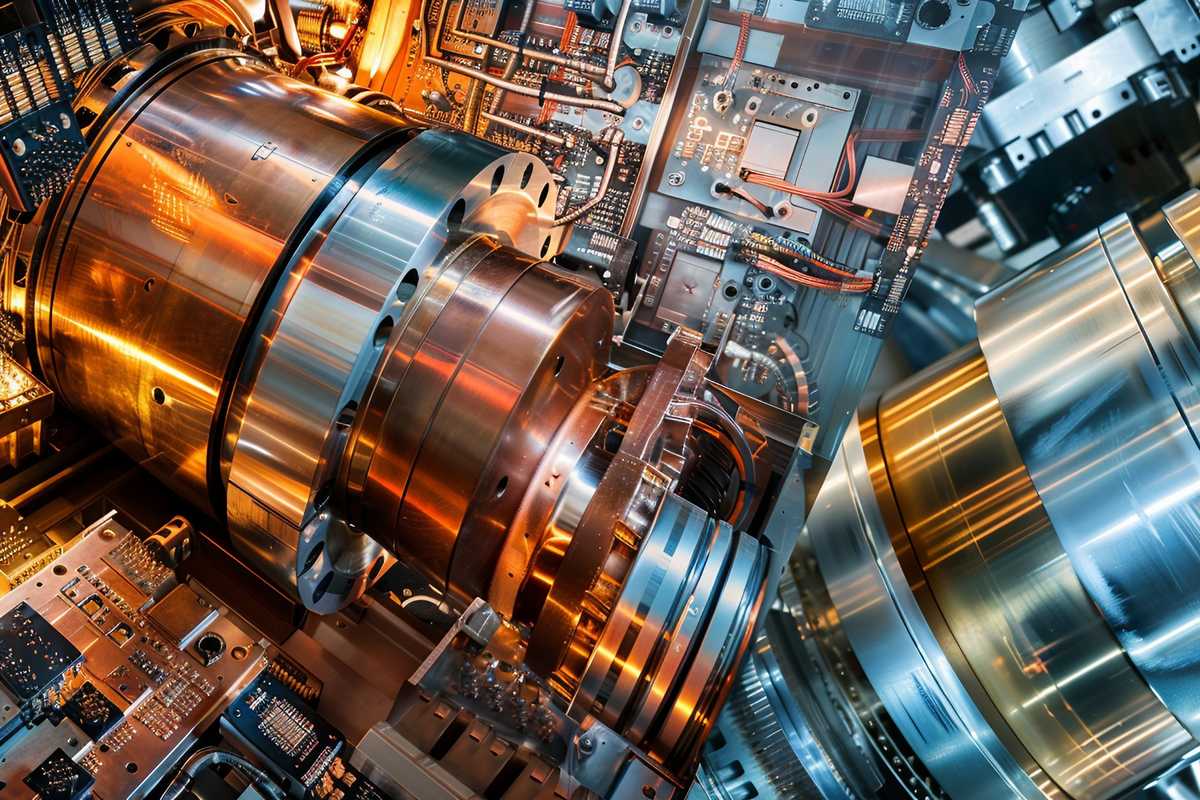

Dive into the colorful world of non-ferrous metals, where functionality meets visual appeal. These metals, devoid of iron, are not only prized for their practical uses but also for the spectrum of colors they exhibit. Each hue not only beautifies but also signifies the unique properties and applications of the metal.

Take copper, for instance, with its signature reddish-brown luster that's not just for show—it's a beacon of its superior ability to conduct electricity. When copper ages, it wears a green patina like a badge of honor, offering protection and a touch of elegance to buildings and statues.

Aluminum's silvery-white sheen is more than just pretty—it reflects light and heat, making it a go-to material for everything from keeping your food fresh to harnessing solar energy.

Brass shines with a golden glow, varying in intensity based on its zinc content. This not only allows for a customizable aesthetic but also makes it a favorite for ornamental designs and musical instruments that catch the eye and please the ear.

Bronze carries a deep, earthy tone, signaling its storied past in art and its current role in reducing friction in machinery. Its robustness is as much a part of its identity as its color.

Nickel, with its bright, silvery finish, stands as a symbol of endurance against the elements, often lending its strength to other metals through plating.

Titanium may look like a simple gray metal, but its lightweight yet robust nature makes it a powerhouse for cutting-edge fields like aerospace and medical technology.

And let's not forget the precious metals—gold and silver. Their lustrous colors are universally recognized, not just for their opulence but also for their excellent conductive properties, making them indispensable in high-tech applications.

The palette of non-ferrous metals is a testament to their adaptability and critical role in advancing industries. From the warm copper tones to the cool titanium hues, these metals are not just about looks—they're about possibilities.

2. The Remarkable Benefits of Non-Ferrous Metals

Non-ferrous metals, those without iron content, are the unsung heroes of modern industry. Their unique properties offer a multitude of benefits that make them indispensable in a wide array of applications.

One of the standout qualities of non-ferrous metals is their impressive lightness. Aluminum and titanium, for example, are much lighter than steel, yet they maintain considerable strength. This makes them perfect for use in the aerospace industry, where every ounce matters. Aircraft and spacecraft benefit from these metals, as they contribute to fuel efficiency and maneuverability without sacrificing structural integrity.

Corrosion resistance is another significant advantage. Metals like copper and zinc are known for their ability to withstand the elements, making them ideal for outdoor structures and marine applications. Copper roofing and zinc galvanizing are just two examples where these metals provide long-lasting durability, reducing the need for frequent maintenance and replacement.

The non-magnetic nature of these metals also opens doors to specialized uses. In environments where magnetic interference is problematic, such as in MRI machines or electronic enclosures, non-ferrous metals like copper and aluminum are essential for their ability to operate without disruption from magnetic fields.

Recycling is a further benefit, with many non-ferrous metals boasting high recyclability without degradation of their properties. This not only supports environmental conservation by minimizing the need for new mining but also promotes a circular economy where metal resources are efficiently reused.

Lastly, the aesthetic appeal of non-ferrous metals cannot be overlooked. Their varied natural colors and finishes are not only visually pleasing but can also be a design feature in architecture and consumer products. The bronze hue of a statue, the silvery gleam of an aluminum car part, or the golden sheen of a brass instrument—all these are examples of how non-ferrous metals combine beauty with functionality.

In summary, non-ferrous metals offer a combination of low density, high corrosion resistance, non-magnetic characteristics, recyclability, and aesthetic versatility, making them a cornerstone in the advancement of various industries. From transportation to construction, electronics to art, these metals are essential in driving technology forward and supporting sustainable development.

3. Harnessing the Power of Non-Ferrous Metals in Industry

Non-ferrous metals, free from iron, are the unsung heroes in a multitude of industries, thanks to their exceptional qualities. These metals, including the likes of aluminum, copper, and titanium, are crucial in driving innovation and efficiency in today's industrial landscape.

Revolutionizing Aerospace and Automotive Sectors

Aluminum, celebrated for its lightweight yet strong nature, is a game-changer in aerospace and automotive manufacturing. It's the material of choice for aircraft fuselages, helping to cut down on weight and fuel consumption while maintaining safety and performance. Titanium, with its formidable strength and resistance to rust, is indispensable for aircraft engine parts and landing gear, ensuring reliability in the skies.

The automotive industry reaps similar benefits from these metals. Aluminum is not just for aircraft; it's also found in car engines, wheels, and body panels, helping vehicles shed weight for better fuel economy and lower emissions. Magnesium alloys, lighter still, are used for intricate components like steering wheels, further contributing to the lightweight revolution in modern cars.

Building a Stronger Future in Construction

In construction, copper's durability and superior electrical conductivity make it a staple for plumbing, roofing, and wiring. Zinc, through the process of galvanization, protects steel from corrosion, prolonging the life of buildings and bridges. These metals ensure our structures are not only sturdy but also long-lasting, reducing the need for costly repairs and replacements.

Powering Advancements in Electronics and Communication

The realm of electronics and communication relies heavily on non-ferrous metals. Gold, silver, and platinum, with their excellent conductive properties, are key in high-reliability components like connectors and switches. Silver's affordability makes it a popular choice for conductive adhesives, while gold's reliability is unmatched in critical applications.

Copper is the cornerstone of the electronics industry, present in virtually every device for its unmatched ability to conduct electricity. It's the go-to metal for printed circuit boards and wires, ensuring our gadgets function smoothly. In communication, copper cables and connectors are the lifelines that keep our world connected, transmitting signals with minimal loss.

The diverse applications of non-ferrous metals underscore their importance in modern industry. Their unique properties not only improve product performance but also drive technological and sustainable advancements. As industries continue to evolve, the significance of non-ferrous metals is set to grow, solidifying their role as foundational elements of innovation and progress.

4. Mastering the Craft of Non-Ferrous Metalwork

Working with non-ferrous metals, such as aluminum and copper, is a craft that demands precision and knowledge. These metals lack iron, which fundamentally changes how they react to heat and manipulation. For those in the metalworking field, understanding these differences is vital to produce strong, functional products.

Welding non-ferrous metals is a delicate process. Metals like aluminum have lower melting points than steel, so welders must carefully manage the heat to avoid damaging the workpiece. TIG welding is a preferred method here, as it allows for meticulous control over the heat and weld pool, crucial for these sensitive materials.

The quick heat dissipation of non-ferrous metals is a double-edged sword. On one hand, it requires welders to apply more heat to maintain the weld pool. On the other, it limits the heat-affected zone, preserving the metal's original properties. This characteristic is particularly notable in aluminum, which is known for its rapid heat transfer.

Oxidation is another challenge when welding non-ferrous metals. Aluminum, for example, develops a stubborn oxide layer that's tougher than the metal itself. To tackle this, welders must clean the metal surface beforehand and use specific filler materials that help remove the oxide during the welding process.

The malleability of non-ferrous metals like copper is beneficial for shaping and forming but can cause warping when welding. To counteract this, metalworkers use support structures and apply heat incrementally, ensuring an even distribution and minimizing distortion.

Shaping techniques such as extrusion, rolling, and forging are commonly used with non-ferrous metals, leveraging their pliability to create intricate and robust shapes. For instance, extrusion is perfect for making uniform aluminum sections for construction purposes.

The ability to create lightweight, corrosion-resistant, and durable components with non-ferrous metals offers vast potential for innovation. However, it requires a solid grasp of the metals' behaviors and the most effective techniques for handling them. With these skills, industries can fully exploit the advantages of non-ferrous metals in a range of modern applications.

5. The Indispensable Role of Non-Ferrous Metals in Shaping Our Future

As we reach the conclusion of our exploration into the world of non-ferrous metals, it's clear that these materials are more than just substances—they are the driving force behind countless innovations that define our modern lifestyle. Their unique properties, such as non-corrosiveness, lightweight nature, and superior electrical conductivity, have made them essential in a myriad of applications that touch every aspect of our lives.

From the aircraft that soar through the heavens, made possible by the lightness of aluminum and the strength of titanium, to the architectural marvels that stand tall against the elements thanks to the durability of copper and zinc, non-ferrous metals are foundational to our progress. They are hidden in plain sight within the electronic devices that connect us, with copper's electrical conductivity at the heart of every wire and circuit.

The adaptability of these metals is not limited to their existing uses; they continue to inspire new technologies and solutions. As we push the limits of what's possible, the demand for materials that can meet the exacting standards of innovation only grows. Non-ferrous metals have consistently answered this call, proving their worth time and again.

Despite the challenges that come with working with these materials, such as the precise heat control needed in welding aluminum or the careful handling of copper to prevent warping, the industry has never stopped advancing. Techniques are refined, and new methods are developed to ensure that the full potential of non-ferrous metals is harnessed.

In essence, non-ferrous metals are not merely contributors to our industrial and technological achievements; they are catalysts for change and progress. Their role in the ongoing advancement of our industries is irreplaceable. As we continue on our path of discovery and innovation, non-ferrous metals will undoubtedly be at the forefront, shaping the future of our world in ways we can only imagine.

Sharing is Caring

Feedback

At WeldWins, we know we aren't perfect which is why we're always looking for ways to improve. You can help us do better by taking 2 minutes to fill out our simple feedback form.

Any and all feedback is welcome. It could be a complaint, an idea, or even just a comment, we'll always be grateful to hear what you think.