How Can You Choose the Perfect Welding Helmet for Safety and Performance?

July 6, 2024

10 min read

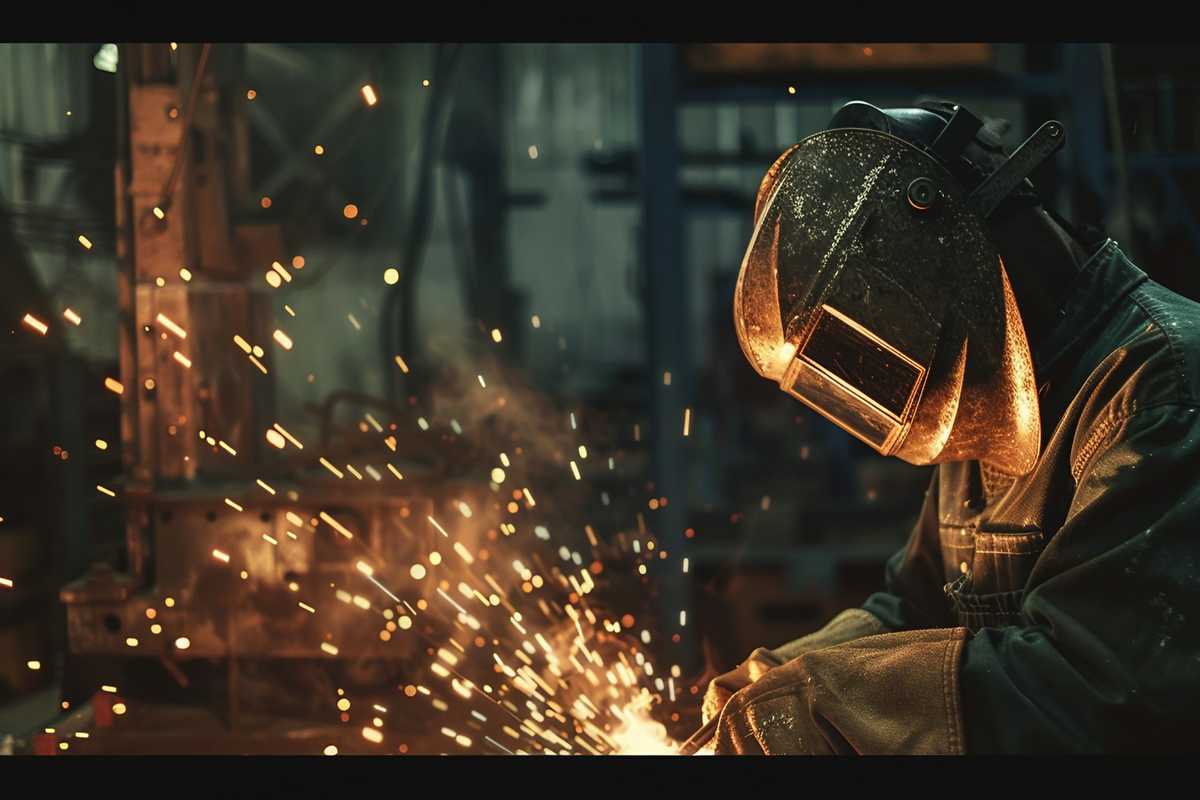

Embarking on the craft of welding demands not just skill and precision, but a steadfast dedication to safety. The intense glare and sweltering conditions inherent in welding pose a significant threat, particularly to the eyes and face. Enter the welding helmet: a vital safeguard, a welder's sentinel. It offers more than just compliance with safety norms—it's a welder's ally against the invisible dangers of ultraviolet (UV) and infrared (IR) radiation, and the tangible threats of sparks and debris.

Selecting an appropriate welding helmet transcends mere regulatory adherence; it's about enhancing the welder's vision and comfort, which in turn, translates to superior welds. A well-chosen helmet can be the difference between a flawless execution and a compromised job, marred by poor visibility or discomfort. Equipped with the ideal helmet, a welder can sustain productivity and artistry even during prolonged periods of work.

This guide is your compass to navigating the world of welding helmets. We'll dissect the types, dissect the features that matter, and guide you through the maze of options. Whether you're a seasoned welder or a novice, recognizing the value of a top-notch welding helmet is your initial stride towards conquering the realm of welding safety. Join us on this quest to uncover the helmet that not only promises optimal protection but elevates your welding journey.

1. Shielding Your Vision: The Critical Role of Eye Protection in Welding

Welding isn't just about fusing materials together; it's an art that requires a keen eye and a clear vision. But with this craft comes a hidden danger—the intense and harmful light that can wreak havoc on a welder's eyes. Protecting your eyes in welding isn't optional; it's as vital as the welding torch itself.

The most immediate threat to a welder's eyes is 'arc eye' or 'welder's flash,' a painful condition where the cornea gets inflamed due to UV light exposure from the welding arc. Imagine feeling like you have gritty sand stuck in your eyes, coupled with an excruciating pain that can even lead to temporary loss of sight. That's what arc eye feels like, and it's a welder's sworn enemy.

But the peril doesn't end there. Over time, the UV light can inflict more lasting damage, such as cataracts—a clouding of the eye's lens that dims your vision and can eventually lead to blindness. The retina, the eye's inner layer that captures light and sends images to your brain, can also get damaged by the intense light, sometimes permanently reducing your ability to see.

Besides the light, there's the threat of physical injury from sparks and metal fragments that can fly into your eyes, causing scratches or more severe harm that could lead to infections or lasting vision problems.

Given these risks, it's clear that a top-notch welding helmet is more than just gear—it's your personal guardian. It acts as a fortress, shielding your eyes from the dual assault of dangerous radiation and flying debris. By understanding these risks and arming yourself with the right protection, you can keep your eyes safe and your vision sharp, ensuring that you can carry on with your craft for years to come.

2. Exploring Welding Helmet Varieties for Optimal Safety and Performance

In the realm of welding, the helmet you don is more than a shield; it's a critical component that influences your work's precision and your safety. With a myriad of welding helmets on the market, each boasting distinct features, it's imperative to discern which type aligns with your welding endeavors.

The Convenience of Auto-Darkening Helmets

Auto-darkening helmets, favored for their cutting-edge technology, offer welders the luxury of lenses that adapt to the arc's intensity. This automatic shading adjustment means uninterrupted work, as there's no need to flip the helmet up to see between tasks, bolstering both safety and efficiency.

Within this category, you'll find variable shade helmets, which cater to welders who juggle various welding processes. These helmets allow you to modify the lens's darkness to match the task at hand. Conversely, fixed shade helmets are calibrated for a specific welding intensity, making them a cost-effective option for those who specialize in a single welding technique.

The Simplicity of Passive Welding Helmets

Passive welding helmets, the traditional choice, come equipped with a non-changing fixed shade lens. To inspect your workpiece pre-weld, you'd need to manually lift the helmet or use an additional shield. While these helmets are more budget-friendly than their auto-darkening counterparts, they demand more effort, which might not be ideal for those who weld frequently.

Despite their simplicity, passive helmets are known for their durability and are a solid pick for welders who appreciate straightforward equipment or those just starting their welding journey. However, for extended welding sessions, they may not offer the same comfort or efficiency as auto-darkening helmets.

Helmets Tailored for Specialized Tasks

In certain welding scenarios, specialized helmets come to the fore, providing features designed for specific conditions. Take the pancake welding mask, for instance, with its round shield that blocks peripheral light—perfect for outdoor pipeline welding. Crafted from lightweight balsa wood, these masks offer a snug fit and superior glare protection.

Leather welding masks are another niche option, delivering exceptional protection against sparks and spatter, often encountered in overhead welding or high-heat situations. These masks are the go-to for welders needing extra defense against the elements.

Selecting the ideal welding helmet is a pivotal step for safeguarding your safety and ensuring the caliber of your work. Whether you lean towards the advanced features of an auto-darkening helmet, the uncomplicated reliability of a passive helmet, or the specialized protection offered by niche models, ensure your choice meets your specific welding requirements and adheres to safety regulations.

3. Essential Attributes of a Welding Helmet

When you're in the market for a welding helmet, it's not just about picking any helmet off the shelf. You need to zero in on specific features that will keep you safe and make your welding tasks easier and more efficient. Let's break down these must-have attributes:

Adjustable Shade Levels

Imagine you're working on different welding projects, each with its own intensity of light. You need a helmet that can adapt to these varying conditions. That's where adjustable shade comes in. It allows you to change the darkness of the lens depending on whether you're dealing with a high-intensity arc or a lower one. This flexibility helps protect your eyes from strain and potential damage, ensuring you can work comfortably on any project.

Power Source Options

The power source of your helmet is like the engine that keeps it running. You have two main choices: solar-powered helmets that harness the sun's energy, making them great for outdoor use, and battery-powered helmets that are reliable no matter where you are. If you're often moving between indoors and outdoors or working in dimly lit spaces, consider how your helmet's power source will perform in those environments.

Clarity and Size of the Viewing Window

The lens of your helmet is your window to the workpiece. A larger viewing area gives you a broader view of your work, which is especially helpful for detailed or precision tasks. Optical clarity is just as important—it's about how clear and sharp everything looks through the lens. A lens with top-notch clarity will reduce eye fatigue and help you produce better welds. It's like the difference between looking through a clean window and a foggy one.

When you're choosing a welding helmet, think of it as finding the right partner for your welding journey. The adjustable shade, the power source, and the lens quality are key features that will affect how well you can do your job and stay safe while doing it. Take the time to compare these features and pick a helmet that ticks all the boxes for your specific welding needs.

4. Prioritizing Comfort: The Key to Enhanced Welding Performance

While the protective capabilities of a welding helmet are paramount, the comfort and fit are equally essential to ensure a welder's safety and efficiency during extended periods of work. A helmet that fits well is more than a mere accessory; it's a critical tool that can significantly improve your welding experience.

A helmet should comfortably hug your head, avoiding any pressure points that could lead to discomfort or headaches. Adjustable headbands are a game-changer, allowing you to customize the fit to your head's unique contours. This customization not only provides comfort but also keeps the helmet securely in place, no matter how much you move or the angles you work at.

The helmet's weight plays a vital role in your overall comfort. A heavy helmet can be a burden, causing neck strain and fatigue that distracts you from your work and could lead to errors. Opt for helmets crafted from lightweight materials to alleviate this strain, enabling you to weld for longer periods without the nagging discomfort.

Good ventilation is crucial in the sweltering environment of welding. A helmet that promotes adequate airflow will help you stay cool and prevent the lens from fogging, which can obscure your vision. Some helmets feature advanced ventilation systems or are constructed with breathable materials to enhance air circulation, keeping you comfortable and focused.

Don't overlook the importance of padding. Helmets with sufficient padding on the headband and contact points can absorb the helmet's weight, making long hours of work more bearable and preventing discomfort that could otherwise lead to frequent breaks and lost productivity.

Finally, the ease of adjusting your helmet is a convenience that cannot be overstated. You should be able to tweak the fit and settings effortlessly, even with gloves on. This feature allows for quick adjustments as you switch between tasks, ensuring continuous protection without the need to remove your helmet.

In essence, a welding helmet that offers superior comfort and a perfect fit is not just a luxury—it's a necessity for any welder aiming to work safely and efficiently. A helmet that feels good and fits well will keep you protected and allow you to concentrate on the task at hand, making you a more productive and safe member of the workforce.

5. Final Thoughts: Selecting Your Ultimate Welding Defender

As we conclude this comprehensive guide, it's clear that the journey to finding the perfect welding helmet is one of utmost importance for both your protection and the excellence of your welding work. We've traversed the landscape of welding helmets, examining the innovative auto-darkening models that adjust to light changes on the fly, the steadfast reliability of passive helmets, and the specialized gear designed for unique welding environments.

The dangers of 'arc eye' and the insidious UV radiation in welding are real threats that demand serious eye and face protection. We've underscored the necessity of a helmet that not only shields you from these hazards but also contributes positively to your welding endeavors.

We've dissected the essential features that elevate a welding helmet from good to great. The ability to adjust the shade level is indispensable for dealing with various welding intensities. The power source—be it solar or battery—should match your work setting to ensure consistent performance. A broad and clear viewing area is vital for meticulous work, and a snug, comfortable fit is crucial for those long hours under the hood.

Your ideal helmet is one that aligns with your individual welding practices, offering a harmonious blend of safety, functionality, and comfort. Quality should never be compromised. Investing in a top-tier helmet is an investment in your safety and in honing your craft.

By placing safety and practicality at the forefront, you're not just protecting yourself—you're setting the stage for enhanced welding accuracy and efficiency. With the most suitable helmet firmly in place, you can immerse yourself in the art of welding, secure in the knowledge that you're fully equipped to tackle any welding challenge that comes your way.

Sharing is Caring

Feedback

At WeldWins, we know we aren't perfect which is why we're always looking for ways to improve. You can help us do better by taking 2 minutes to fill out our simple feedback form.

Any and all feedback is welcome. It could be a complaint, an idea, or even just a comment, we'll always be grateful to hear what you think.